Ground Tackle - Windlass

Pau Hana came with a very robust windlass, Royal by Lofrans. It is a manual windlass, uses no power, works flawlessly & has a warping drum. It is a very nice unit and pretty pricey.

Here's the problem...It's a lot of dang work to pull the anchor even a short distance! To add to that, it is slow to retrieve, which can be a problem when you are boating single handed or need to get the "hook" up in a hurry. It is however, mostly a problem for my deckhand (wife) as she is the one usually doing the anchor dropping/retrieving. I just couldn't let her suffer anymore.

I bit the bullet & purchased a Lewmar Pro-Series 1000 from West Marine as I have a Port Supply account which usually gives me a pretty good discount.

In anticipation of receiving the windlass, I downloaded the manual & ran the power wires. I planned to use the Negative terminal at the Bow Thruster (located under the forward berth) since it has a wire run from the engine room using 2/0 AWG wires with posts. This would make for a short run of less than 8' to the windlass and save wire. From the engine room I ran a new positive wire through the rigging tube. I also ran an additional "pull string" so I would easily be able to get the switch control wires back to the lower helm. The online manual showed the appropriate wire size for the length of the wire run. I chose the largest gauge, 8 AWG as indicated.

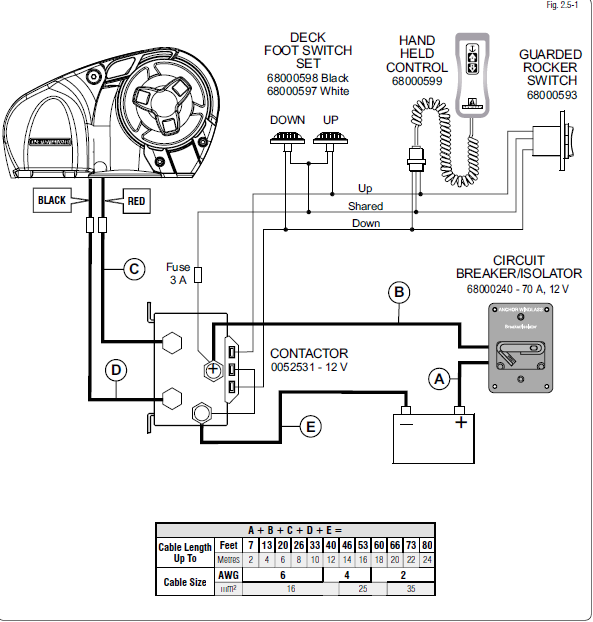

The windlass showed up about 2 weeks later. The first thing I noticed as I read through the instruction manual, was that the wire chart was different. It actually called for using a larger gauge wire! Crap! I contacted Lewmar and they sent the diagram below stating that this is the correct configuration.

**A note about DC wiring, and here is where many folks get into trouble. You must add ALL of your wire runs together when figuring the length vs size/gauge of wire. From the battery to the component and back. So in the drawing above the actual wire length would equal A + B + C + D + E the total of both the Black and the Red wires.**

The size of my wire based on the run would not be adequate. I decided to go back to my original plan and use the Bow Thruster connections for both the positive & the negative. The thought is, the bow thruster & the windlass are never run at the same time.

|

| Wires at Bow Thruster |

First up was to remove the old windlass. Clean the area. Fill the old holes.

|

| Removing the old Manual Windlass |

Next I made a clear Acrylic template on the Laser to be sure of the layout. I had to make a few adjustments to the measurements.

|

| Acrylic Template for "Testing" final location |

Once I was satisfied with the layout, I made a new base from 3/8" Starboard on my CNC.

|

| Starboard Base |

After the Starboard base was Siliconed and screwed in place, I used the holes as guides for the new mounting holes, Siliconed again around the holes and laid down the rubber gasket.

|

| Silicone sealing |

I Siliconed the base of the windlass and set it in place. I snugged the 3 nuts but waited until the following day to tighten them up to give the Silicone time to cure.

Day 2. With the windlass in place I installed the 2 foot switches. To make the process easier I removed the 2 drawer cabinet under the bunk which provided plenty of access. I say it every time I have to work on this boat, access to virtually everything is good and well thought out.

The easiest and straight forward way to get the wires from under the bunk to the anchor locker meant fastening them to the forward bulkhead and then going through into the anchor locker. It wasn't ideal as far as aesthetics but worked. The only other possible solution would have meant bringing them into the bottom of the anchor locker, but that would have meant they would be covered with chain and/or anchor rode. That seemed like a bad idea.

|

| Forward Cabin wiring |

Next I proceeded to run all the switch & power wires. Red for power, Black or down, Blue for up. It took some head scratching as I had to make sure I combined additional switch wires to the controller for the helm switch, which would be installed last.

I installed the 70 AMP breaker under the step to the bunk where I could get to it easily & installed the 3 AMP breaker for the switches a little out of the way in the bow storage compartment but still accessible.

|

| Windlass Breaker - Out of the way but accessible |

With everything but the helm switch installed, I dropped a piece of paracord down in the windlass, tied the chain to it & pulled it through & reconnected the anchor.

|

| Rigging the Chain/Rode |

I tested the unit before buttoning up everything. Success!!

Now to the helm switch. I decided the main switch would be best at the helm rather than the flybridge as it seemed logical that in bad weather or an emergency, I would be pulling the anchor from inside. In normal anchoring situations and for ease of washing the chain and rode, the anchor would be weighed from the bow using the foot switches.

|

| Finished Product |

I pulled the red (power) - black (down) & blue (up) wires using the pull string and routed them up to the helm. I am running out of space to mount things but below the throttle seemed to be a good option. I installed the wires and connectors to the switch BEFORE installing the switch so that I could test it and make sure that up was indeed up & down was down. Got it right the first time!

|

| Lower Helm Control |

With everything working, the final item was install a leash made from plastic coated cable to the bow roller to secure the anchor when not in use. I used to have a bungee there but I think this will be easier to use.

|

| Added "Insurance" |

Now for some overnight testing!

Comments

Post a Comment