Engine Cooling Should be Alarming

What can at the very least be a small nuisance and at the most be the nail in it's coffin disaster is a raw water restriction or flow decrease and engine overheat in a diesel engine. It can be very preventable just by constantly scanning your gauges. But it only takes a few seconds for some type of raw water flow reduction or impeller destruction to turn your engine into toast.

A project I had planned from the beginning was High Temperature Alarms. I installed them on a previous boat, a Luhrs 320. I know they work like they are supposed to because not long after installing them (2 engines) my port engine must have sucked up a plastic bag or something & instantaneously the Raw Water Alarm went off. I pulled back the throttle, shifted to neutral and the alarm shut off & the engine temp dropped. At 25 mph and a butt load of seawater being cycled through the engines, this small event could have been cataclysmic but instead it was a hiccup.

The Camano moves much slower but a raw water alarm is no less important.

The alarms I installed (same as the alarms I installed in the Luhrs) are made by Borel Manufacturing. I like them for 4 reasons. 1. They work, which I know from what I relayed above. 2. They are not terribly expensive. The system for the Camano totaled $121.00. It consisted of a single alarm panel for the lower station & a remote alarm for the flybridge. I only needed some additional wire & a couple connectors. 3. They are easy to install. I was able to install the entire system in less than a day, about 4 hours. 4. They are made in the USA.

I started by drilling a 2" hole in about the only place I could find in my lower station console. I would have liked it to be right next to the Volvo's temperature gauge but I just couldn't make that happen.

The upper station remote alarm fit very nicely on the face of the console above the throttle & shifter.

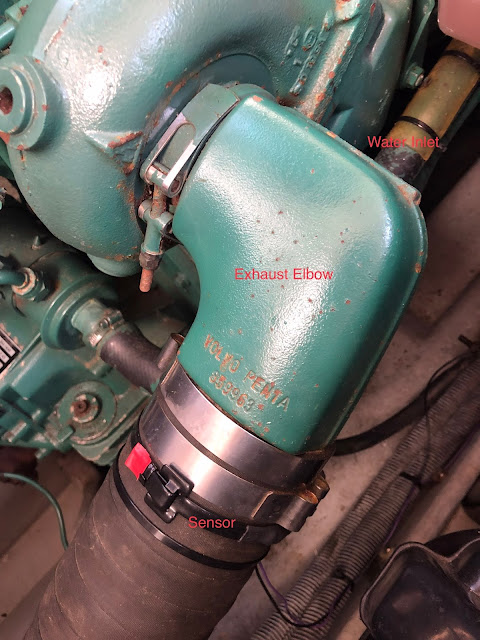

Next I fastened the alarm sensor around the exhaust hose just below & 90 degrees from the water inlet. The band simply wraps around the hose and turns back on itself. I cut off the excess band & zip tied the sensor wires to the hose. There are 2 short brown wires on the sensor that are used as test wires.

The sensor's black wire went to the negative ground nearby and I routed the purple wire back to the alarm panel at the lower station. The purple wire is 10' long so I needed to splice a short length of black wire to it to reach the alarm panel. I used black for this as it fastens to the (-) on the alarm panel. I then installed a short piece of red wire from the (+) on the alarm panel to the engine ignition switch power.

Once that was complete, I routed a red & black from the lower alarm panel to the upper alarm panel & made the connections there. That's it, done, easy peezy.

If you are interested here is the link to Borel Manufacturing https://www.borelmfg.com/

Comments

Post a Comment