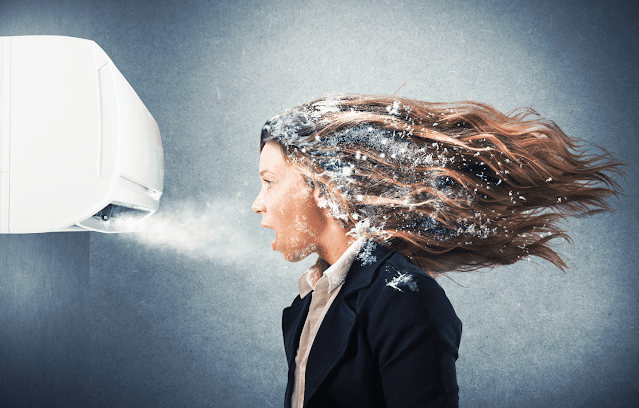

“You’re as cold as ice...Part I” No, not really

I think that one of the advantages to the Camano is all that glass surrounding the cabin and the exceptional view it gives you. It does however challenge the cooling system. These boats were made in the Northwest so the difference there compared to the humid tropics is certainly different. We have a Marine Air 16,000 BTU unit located under the salon bench. There is a thru hull strainer to a pump in the engine room.

When we purchased the boat I had my AC guy check the freon in the unit as it would frost up. That took care of the problem. I cleaned the condenser coil fins and installed a new washable filter. For a 21 year old unit it works great. It was just a struggle for it to keep the boat cool when the heat of the day was bearing down. The boat also has Phifertex snap on screens for the side windows and a canvas cover for the front windshield as well as curtains on the inside. All of this helps but still the coolest we could get it was 78 deg inside, not bad but a little tough to sleep since by the time the air got to the bunk it was warmer there. We mounted a fan by the AC vent and that helped some.

A few weeks ago I opened the cabinet under the sink and noticed it seemed cool under there. Hmm, an air leak? I decided to do some boat CSI. The AC unit feeds a trunk line that goes to the main vent in the salon via a distribution box which then goes to the galley and a distribution box under the cabinet to the bunk. I checked the distribution boxes and noticed there was some air leaking at the galley. I was able to caulk the connection with some silicone. To access the salon box I needed to remove the salon bookcase, but in order to remove that I had to remove the main register. As soon as I got behind the area I found the problem. The distribution box had broken away from the wall and cool air was flowing back behind the port side of the boat.

|

| After I had removed the screws |

|

| Cabinet & Bookcase Out |

|

| Fun Spaces |

The edges of the box was screwed in the 4 corners and 3 of those corners had broken. I disconnected the flex duct which was screwed to the outlet and had a large hose clamp and was taped! I removed the screws and box and applied some Butyl tape to the box edge and re-drilled holes for the screws. Once I had the box on, for good measure I taped the edge with foil tape.

As hard as all that was, the most difficult part was getting the flex duct back onto the box outlet, especially since the first couple inches were “boogered up” and had to be cut off. The Shortened piece was a little Tough to put on and reinstall the band clamp.

In narrating this event I have left out the expletives, there were quite a few.

With everything back together, it was apparent that the volume and force of the air from all of the registers had increased. Success!

UPDATE: I have another Blog entry about more AC issues - see "Your As Cold As Ice...Part II"

Comments

Post a Comment